By Blake Harper 18 June 2025

Ever bought something just because the box looked too beautiful to resist- like a perfume, chocolate gift, or some tech gadget? You are not alone!

Studies show that 72% of American consumers make their buying decisions just because they like the custom packaging design. One of the driving reasons behind this behavior is the use of premium custom finishes like embossing, debossing, spot UV, and foil stamping.

Just think of an Apple iPhone Box- how simple, sleek, minimal, and incredible it looks! Or consider the gold shimmering logo of a premium Godiva chocolate display box. These touches are quite thoughtful and not at all accidental. Such brands deliberately make their design choices that aim at delivering luxury and prestige. These techniques not only enhance the overall visual and tactile appeal and texture of your product boxes, but also foster an emotional bond with the buyers, creating more meaningful, memorable, and interactive experiences. Together let’s delve into what are the most premium finishes in custom packaging, how they work, their benefits, cost considerations, uses, and most importantly, how to choose the right one for your brand.

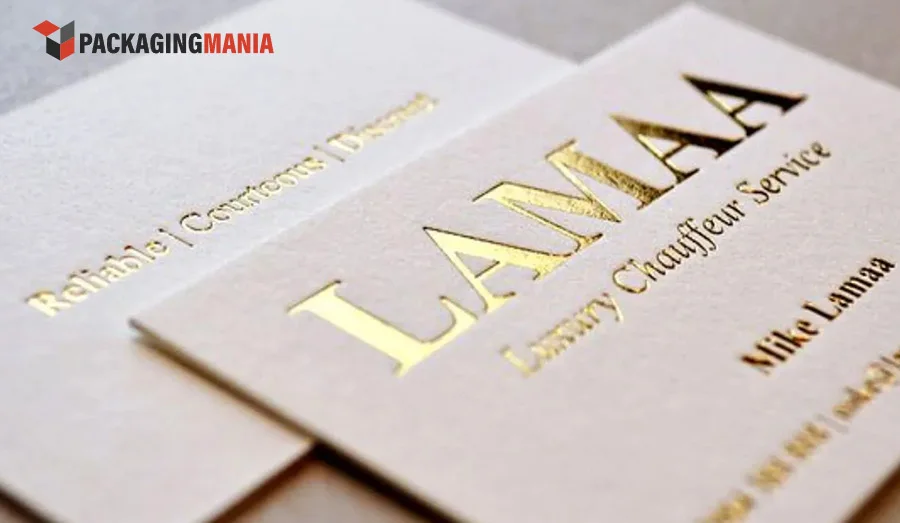

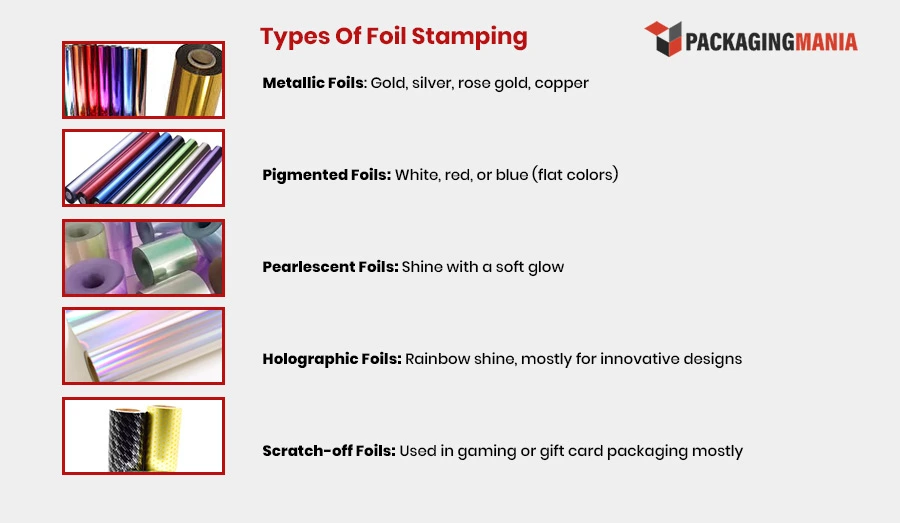

This specialty process is one of the most seen ones in luxury product ranges, utilizing heat and pressure to transfer the metallic foil film and accents on packaging boxes and create a shiny effect. Most of the time, this custom printing and finishing technique is used to highlight specific areas and elements of the box design such as logos, borders, and specific design parts. This method adds a metallic sheen to the box and helps instantly grab the attention of the buyers.

Keeping in view your artwork and box design, a metallic die is accordingly created. The metallic foil on a roll is then placed over the box material. The die is then heated and pressure is applied to sandwich the foil between the surface of the box and the die. This heat ensures to stick the foil firmly to the box surface and bring a perfect metallic foil layer on the material.

Foil stamping adds to the visual appeal and box aesthetics as well as elevates your brand image by adding more value to your custom rigid boxes and other box types. It has diverse applications and works well on different mediums such as custom labels, boxes, tags, and cards. Due to its durable nature, it is highly resistant to fading and thus adds a premium touch to your brand.

Foil stamping is mostly used on:

Spot UV is a popular custom finishing method that applies a selective glass coating on certain areas of the box where a brand wants to enhance the overall contrast, shine, and texture. It plays well with light and brings out a shimmery effect of layered polish over the custom printed elements on the box.

Spot UV uses a UV coating that is to be applied on certain parts of the box via custom printing (mostly screen printing). Once the box is coated, it is further passed under UV light that cures and hardens the coat instantly. The selected box parts then become glossy while the rest of the box stays matte and non-reflective, and this creates a perfect contrast, bringing the glossy elements to more attention.

Spot UV offers a lot of benefits such as putting the box design to the main focus and drawing greater attention to specific box areas such as logos, social media handles, or the brand slogan. Overall, it delivers a great sense of luxury by creating a visually appealing gloss contrast on matte backgrounds. Further, it lends a protective layer that shows resistance to moisture, smudges, scratches, dirt, and fingerprints. Eco-friendly options for this coat like water-based and VOC-free ones have also been introduced recently.

Spot UV is mostly used on:

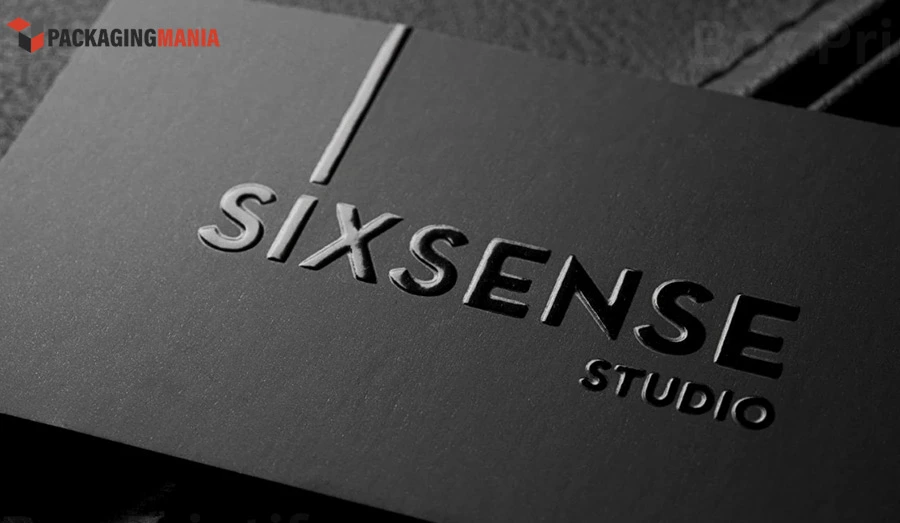

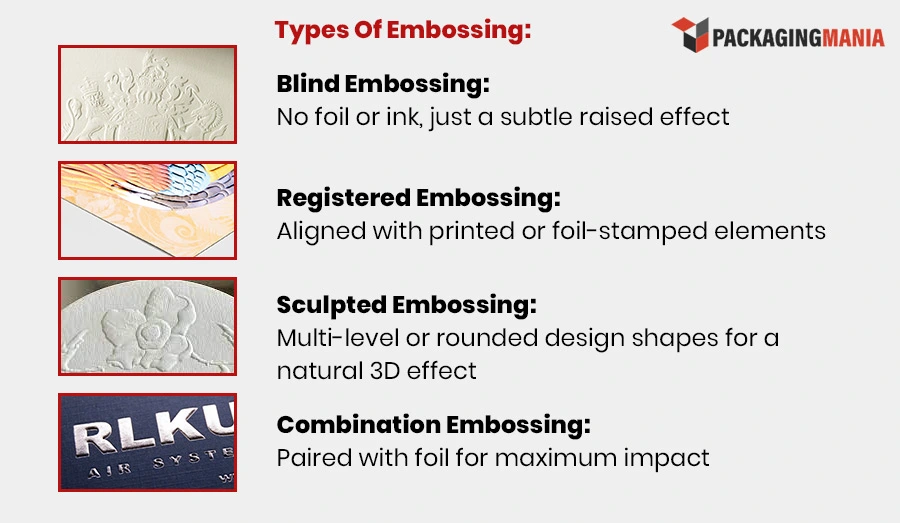

With the embossing technique, brands can successfully add a raised effect to their packaging. This method raises the surface of box material to create a 3D-like effect and lends an extra layer of texture, tactile appeal, and elegance to your product boxes. It not only appeals to your eyes but also feels great to touch.

Meanwhile, check out the complete details of embossing or debossing in our packaging guide.

First of all, two dies are created from your given box design and the packaging substrate is placed between them. Then high pressure is applied onto them to push the material in an upward direction in the same shape as the given design.

Embossing gives an overall elegant and premium look and feel to your custom boxes with more visual depth by creating dimension to your brand’s logo and artwork. It brings more versatility to your box design and works great for minimal or complex designs that are otherwise hard to stand out. No harmful or toxic inks or chemicals are used during the process and just pressure is applied, which makes it a great eco-friendly choice.

Now that we have discussed foil stamping, spot UV, and embossing- the premium box finishes in detail, it’s time to shed light on some other popular choices as well.

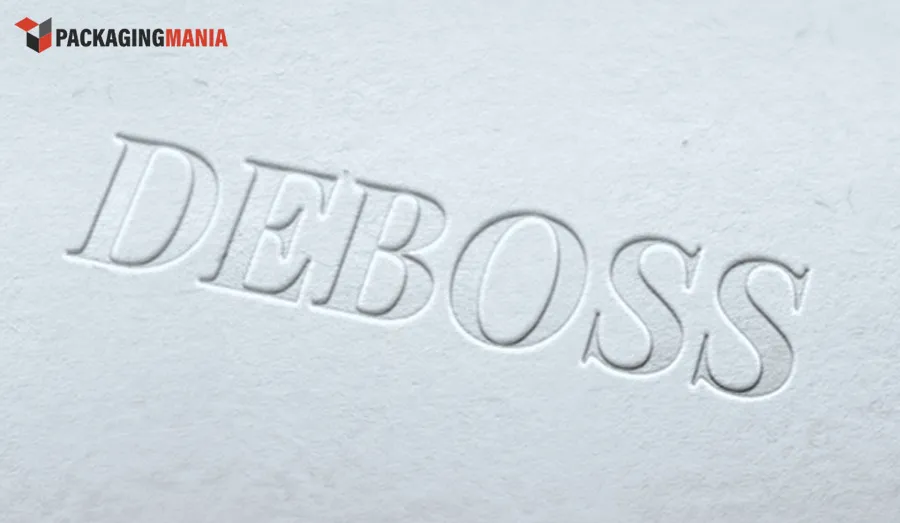

It is actually the total opposite of embossing. Instead of raising the box surface, it presses the design into the material, that too by applying pressure, for a recessed or sunken look. Brands use debossing as it is subtle and classy and offers a better control for think fonts. Further, it pairs really great with foil stamping or spot UV for a more indented and shiny effect. Most of the time, you can see its usage in luxury leather packaging, wine boxes, and rigid packaging.

Soft touch coat provides your custom boxes with a velvety, suede-like finish that is smooth and luxurious to touch. It is not only attractive for the eyes but also great to touch, with a distinctive feel, and instantly evokes a feeling of elegance, quality, and indulgence. When a consumer comes in contact with such a box equipped with soft touch coating, it conveys a message of the product’s high-end nature. Further, it works well in creating emotional links and boosting brand engagement. You may mostly find it on smartphone boxes (such as iPhones or Samsung Galaxy). It is also widely used in presentation kits, gift boxes, subscription packages, skincare, and the cosmetic industry to softness and luxury to creams, serums, or makeup boxes.

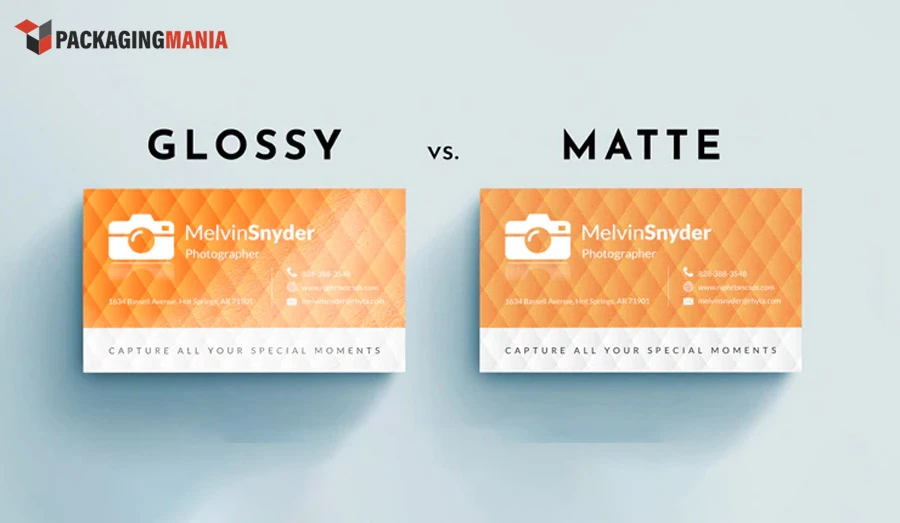

Though gloss and matte laminations might not be as flashy as the aforementioned ones, they serve a great purpose in both protecting the package as well as enhancing its appeal and feel. Lamination refers to a clear coating that is applied on the surface of a box to provide scratch, fingerprint, and moisture resistance. Gloss lamination creates a sleek and mirror-like appearance, to make the colors pop and appear more vibrant and light-hearted- works best for toys, snacks, or children's products.

Conversely, matte lamination gives a non-glossy appearance that is smooth and elegant to touch. It is a trendy option for achieving modern, high-image packaging that appears clean and minimalistic, such as the product packaging for luxury electronics, cosmetics, or fashion products. Though lamination is quite underrated, it greatly contributes towards making your boxes look good and last longer.

Luxury finishes are not just about making a box pretty; they also shape the way people see and perceive your brand. When a person encounters your product, probably they will probably take less than 3 seconds to make an opinion about it. First impression really matters, that is why high-end finishes such as foil, embossing, or soft-touch coating can make a difference. Such finishes also provide an extra thrill in unboxing, which is a considerable aspect in the case of influencer videos and social media posts. When beautiful and creative packaging is posted online people love to share it. In the long run, these minor elements contribute to the creation of a better and stronger brand. When a customer recalls the way your packaging looked and felt, they will be more inclined to purchase again. Therefore, high-quality finishes not only concern the design but also help your brand grow and keep the buyers hooked up to your brand!

One of the most noteworthy aspects associated with luxury packaging is the cost factor. As these finishes are mostly used for luxury purposes, the costs might get increased. However, their higher retail prices can be justified with an increased perceived value and skyrocketing sales.

Here are the possible reasons that result in the increased product costs of these finishes:

• Use of special materials (foil rolls, dies, screens)

• Setup charges (especially for custom dies)

• Labor intensity

Check out these top-searched questions about custom finishes:

Yes. It is a common practice to combine multiple finishes such as spot UV/embossing + soft-touch+ foil stamping together. There are many other combinations of finishes as well and thus combining them on a single box works totally fine for brands.

Yes. Foil stamping is more durable as it doesn’t fade like ink and can easily withstand smudging, fingerprints, or moisture. Moreover, it works great for long-term shelf products.

Yes as the modern one is VOC-free and made with a non-toxic formulation, this makes it safe for both people and the planet.

Embossing is an ideal finish as it lasts permanently and there is no specified time for it. As the design is literally shaped into the material, it won’t wear off.

There are some of them like embossing and foil stamping that may take a few more days for die-making or setup, and their end results make it worth the wait.

Sure, you can use it. Kraft paper is quite flexible towards printing and finishes and thus responds well to it, with a rustic and organic look.

Spot UV is used to target specific areas for highlighting. Whereas, regular UV covers the entire surface.

Foil stamping and Spot UV both work great for logo highlighting. While foil stamping gives a shiny effect and metallic touch, spot UV adds a subtle gloss on the matte surfaces.

Hope you had a good read. To wrap it up, premium finishes are far more than just luxury looks and serve well as a branding tool. No matter if you are a luxury candle brand or a skincare one, these small details can drastically show great results that work in the favor of your brand. So, the next time you think of designing your custom packaging, don’t just stop at printing and rather look up for enticing finishes to give your product boxes a unique look.

Want to try out the best custom boxes in the US? Contact Packaging Mania now!

16 July 2025

28 June 2025