By Blake Harper 14 June 2025

SBS, which stands for “Solid Bleached Sulfate”, is a highly durable paperboard famous for its chic-clean white appearance and smooth surface. Its benefits, flexibility, and durable nature make it one of the top contenders for the best custom packaging material. This high-quality material is used mainly in luxury custom packaging boxes, for packing items from signature perfumes to pharmaceutics and gourmet food packaging. Let’s walk through everything you must know about SBS paperboard, its composition, thickness options, benefits, and factors that declare it an ideal custom packaging choice.

It is a premium-grade paperboard that is made of bleached virgin wood pulp. The word “solid” refers to the single material usage for making the board, unlike layered or composite boards that combine different pulp types. “Bleached” means that the pulp has been whitened via the bleaching process. Whereas, “sulfate” comes from the Kraft process that is used for its making and further helps strengthen the board’s durability and rigidity.

SBS paperboard is mainly known for its bright and clean white appearance and superior printing capabilities. Mostly, it is a hot favorite choice among industries that demand high-quality graphics, aesthetics, and durability, such as cosmetics, pharmaceuticals, high-end retail items, and frozen goods.

To understand why SBS material is so popular, brands need to first consider how it is produced. SBS paperboard is manufactured using softwood or hardwood trees (usually pine or spruce) that are characterized by their long and strong fibers. These trees are logged, stripped, and chopped into little pieces and the wood chips are then passed through the chemical pulping process called the “sulfate” or “Kraft” process that involves cooking at high pressure to extract the cellulose fibers out of lignin and other wood elements.

Upon separating the fibers, they further undergo bleaching to erase any impurities that may remain and whiten the pulp. This bleaching stage is of great importance as it gives the SBS board its signature pure-white look. Once bleaching is done, the pulp is pressed into sheets to obtain the required thickness level. One can also add coatings (clay or polyethylene, depending on the end use) to make the sheets more printable and resistant to moisture. The end result, SBS paperboard, is a strong yet lightweight and attractive material that is adaptable to all customization changes.

SBS paperboard boasts a simple and consistent structure, with complete uniformity from top to bottom. Unlike other recycled boards that comprise mixed layers and a touch surface, it provides a completely smooth and ready-to-print surface. This makes it quite suitable for applications that require embossing, foil stamping, die-cutting, and sharp printing. Further, each layer of the board provides the best-refined surface for packing different intricate designs.

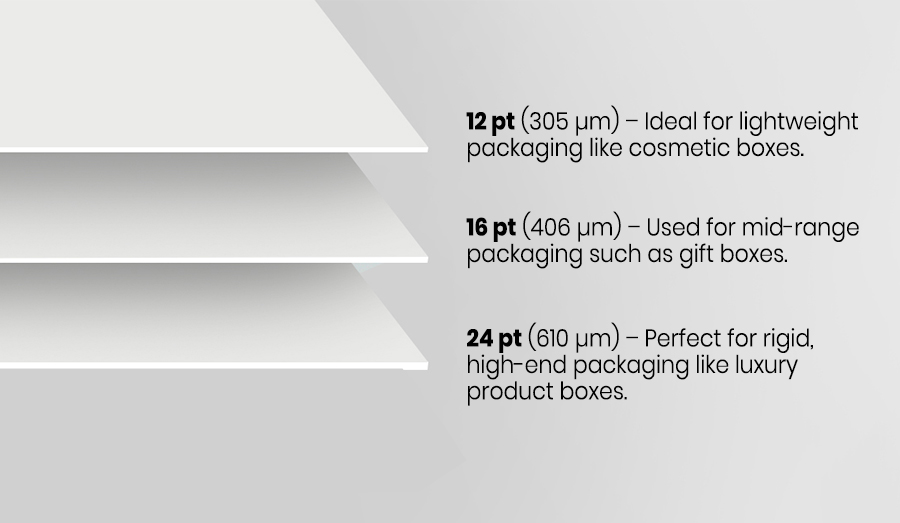

You can pick up from different thickness ranges of the material that is usually measured in points (pt) or grams per square meter (GSM). Common thicknesses range from 12pt to 24pt. However, thicker and specialty grades are also available and the thickness choice totally depends on the type of product that is going to be packed inside the box.

SBS paperboard is a quite preferred material when it comes to brand choices as it can easily fit different industries and products. Most commonly, its usage can be seen in the beauty and personal care industry, as cosmetic boxes, perfume cartons, and skincare packaging. All of the mentioned products must appear high-end and need to look as luxurious as ever, a purpose that SBS can easily achieve.

It is also widely used in the food and beverage sector in the packaging of frozen foods, bakery products, chocolate boxes, and takeaway containers. The fact that it can be coated to make it moisture-resistant and has an excellent print surface makes it ideal to use. In the healthcare industry, SBS is mostly used in making pharmaceutical cartons, over-the-counter medicine boxes, and medical device packaging.

Its white color makes it look clean and gives the impression of reliability, whereas its strength provides maximum product protection. SBS is also a preferred choice for packing mobile accessories, earbuds, and lightweight gadgets from the tech and electronics world. Brands can add custom finishes and graphics of their choice easily onto the paperboard to make the packaging highly tailored to their offerings and persona.

Custom packaging does more than protecting your products during shipping and serves as an effective branding tool as well. With SBS paperboard, brands can easily depict their identity via custom packaging. To achieve this, they can use different ways such as pairing a matte skincare box with gold foil stamping or equipping colorful snack boxes with vibrant illustrations, all thanks to the powerful and flexible SBS paperboard material.

Whether it is a window cutout, embossing, metallic ink, and soft-touch coatings, the material can easily be custom-designed to make the entire unboxing experience truly special for the customers and resonate with the needs of the target audience. Since the board is uniform in texture and color, you can still enjoy the same quality print outcome with each and every package and maintain brand consistency across different product ranges.

The ultra-smooth structure of SBS paperboard provides a great surface for flexible printing and serves as a dream for designers and printers as it holds inks really well and brings out more vibrant colors and intricate images. No matter if you want to print your artwork, illustrations, or solid blocks of colors, you are going to get crisp and sharp results every time on SBS paperboard whose high quality surface is also quite ideal for custom finishes like embossing, debossing, foil stamping, UV coating, and spot gloss. Using such finishes can further enhance the tactile and visual appeal of the packaging, lending it a more premium and high-end feel.

Brands vying for the top market spot and a strong first impression must instantly turn towards SBS paperboard to bring their products to the best possible light whether in consumers’ hands or across the shelves. Therefore, if you want to include detailed artwork and premium branding across your packaging, then SBS can surely serve as the best canvas or backdrop for all your customization needs.

SBS paperboard may though appear smooth and classy, but it has no match when it comes to strength and durability. The board boasts great structural integrity even when a lot of pressure or stress is applied, all thanks to the use of virgin fibers. Even it can hold really well during all the processes including folding, creasing, gluing, and die-cutting, making it an easy-to-go choice for manufacturing. SBS also shows great resistance properties towards cracking along fold lines, an issue that can be a problem with some lower-end boards. Hence, even after scoring and folding, the packaging never loses its integrity and remains clean and professional at all times.

When it comes to products that need extra protection like fragile electronics, food, or pharmaceuticals, SBS paperboard provides a trusted barrier and lends great safety to such items. Naturally, it is not waterproof, but can be coated or laminated with moisture-resistant layers, to make it suitable for refrigerated and frozen foods. SBS can also be laminated with polyethylene and used for liquid containers such as milk cartons, and this explains how versatile it is when it comes to custom packaging choices.

Sustainability is no longer a trend but rather a duty in the modern world. Consumers are becoming more aware of the safety of the planet and how waste generation adversely affects it, thereby reconsidering their purchasing decisions. The same goes for brands that tend to seek more eco-friendly options. SBS paperboard serves as a great choice in this regard when sourced directly through sustainably managed forests. A lot of SBS products are also certified by organizations as Forest Stewardship Council (FSC) or Sustainable Forestry Initiative (SFI) which ensures that trees utilized are responsibly harvested. Since SBS is made using virgin fibers, it can be recycled completely and is also highly biodegradable in nature.

Once it is consumed, it can be introduced into normal paper recycling streams and reused for making other paper items. SBS is compostable, unlike plastic packaging that may take hundreds of years in landfills. With that said, not every SBS packaging can show equal properties as some of them might come laminated with plastic films in large amounts, which might make it hard to recycle them. Thus, brands seeking to remain sustainable need to consider recyclable coatings or should give up on the use of non-compostable finishes as much as possible.

Brands might think of the added expenses when it comes to buying SBS. At the first glance, it may appear a bit costly, but the end benefits are much more than you can imagine. SBS paperboard boasts a great number of benefits, but still, it might be a bit more costly as compared to other chipboard or recycled board options. The main reason is that it is made of virgin fiber, and uses advanced methods as well as high-quality finishes. Nevertheless, the additional expense is worth it to many brands in terms of better quality, print output, and customer impression. The investment in SBS actually pays off in the long run, making your packaging the centre of marketing and customer experience, and declaring it a great choice for packing luxury goods, cosmetics, and specialty foods. It not only makes the product look better but can also help add more value to it, thus leading to better sales and brand loyalty. Therefore, despite a bit high cost, brands must consider SBS paperboard if they want to entice the target audience and direct them for impulse buying. The best thing is, they will be getting the best value of money that they are paying for, so it’s a win-win scene in any case!

Here is a brief comparison of SBS paperboard with other packaging materials:

CCNB uses recycled material in making, which makes it quite a cheap choice but a less refined one. SBS, on the other hand, is made of virgin pulp and yields better print quality and brightness.

SBS paperboard is preferred for premium applications and is fully bleached. Whereas, FBB features mechanical pulp in its middle layer and is used for achieving affordability in custom packaging.

It is obvious that plastic is not favorable for the environment but offers great moisture resistance. Whereas, SBS is not naturally moisture resistant, but can be coated for added protection and is highly recyclable and eco-friendly.

SBS paperboard makes it to one of the most reliable and durable materials, with its smooth and bright finish, structural strength, and aesthetic charm. It serves as an all-in-one option for strength, beauty, and sustainability together in a single frame. With SBS paperboard, brands can take their product display to the next level and create lasting impression on customers. Its tough and durable composition withstands the packaging process, and recyclable nature well-aligns with the goals of those who want to support the planet with eco-friendly choices. If you are in search of custom packaging that can be instantly noticed, SBS paperboard is, by all means, one of the best materials to opt for. We promise you won’t regret your decision!

Choose Packaging Mania for highly versatile custom packaging solutions and enjoy exclusive discounts on custom boxes!

16 July 2025

28 June 2025