By Blake Harper 17 June 2025

Shipping is an essential part of business practices. Brands go to great lengths to ensure that their parcels reach buyers in mint condition. Many brands opt to add fancy elements to their Shipping Boxes to make them look more attractive and provide a better unboxing experience. However, to ensure that products reach the end user unbroken and in a pristine form, the box dimensions must be 100% accurate. Simply put, a wrongly sized box means problems, especially when it comes to fragile and delicate products, and we don’t want this to happen to you.

At Packaging Mania, it is our goal to not only offer exceptional custom boxes to brands but also educate them in improving their packaging. This blog is just another example of it. On this page, you will find a well-researched and in-depth shipping box size guide. After reading this blog, you will be able to:

Let’s start our journey into the world of shipping boxes.

The shipping box dimensions matter a lot because they impact a lot of things like delivery costs, product safety, and sustainability. Let’s explore these factors so you can understand the importance of selecting the right shipping box size.

Every leading shipping company in the US, including FedEx, DHL, UPS, and USPS, charges brands based on the dimensions and weight of the box. If your box is large, it will cost more to send to your customers. Simply put, an oversized box will result in more shipping charges and decrease your delivery cost. Hence, we would suggest getting boxes that are as per the size and shape of your products. A snugly fit box helps cut shipping costs extensively.

Another important factor in the realm of selecting the right shipping box for fragile products is the packaging cost. It is no secret that a large box costs more to manufacture because more material is used in it. On the other hand, a box with dimensions as per your product’s size keeps the cost in check. Moreover, a large box also requires brands to use more filler, which leads to more spending on preparing the order for delivery.

This, in no way, means that you start using small boxes to cut packaging and shipping costs. They are bad for your product and brand image in their own ways, such as no space for cushioning, reduced shock absorption, and increased chances of box bursting during shipping. The best way out is to opt for custom packaging for fragile products, as it allows you to get a box exactly as per your needs.

The right shipping box for fragile items will ensure product safety and guarantee that it reaches the buyers exactly like it left the warehouse. Protective packaging made in a precise size prevents free movement during shipping and keeps the product intact. Items like candles, glass products, and eyeglasses can greatly benefit from this.

Modern-day buyers care a lot about the impact of their shopping practices on their environment. This is why creating a sustainable image in the market is very important for brands. If your brand uses a box that is made from eco-friendly materials and doesn’t use extra material, buyers will automatically understand your efforts in this domain. As a result, they’ll prefer buying from your brand repeatedly. On the business front, this is excellent as it allows you to build a base of loyal customers.

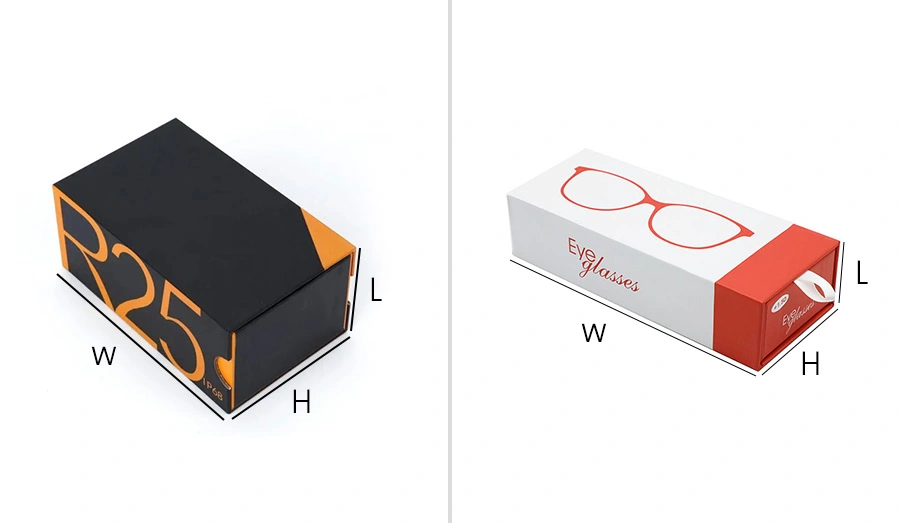

The biggest question that comes to mind while selecting shipping boxes is how to choose a shipping box size that doesn’t damage products or increase the cost. The answer to this question depends on the size of the product. First, let us explain how to measure your product size. It is quite a simple process, and you only need a measuring tape, a pencil, and a paper for taking some notes.

First of all, place your product on a flat surface and find out the length, width, and height (L x W x H). This will give you the product dimensions. Make sure you measure your product at least 3 times to eliminate the chances of any human error. Take the dimensions in inches, as it is mostly used by packaging suppliers. You can also check out our box dimensions guide if you want to learn more about it. Some products come with accessories, so don’t forget to measure them as well.

If you are a reseller selling products in boxes with your brand’s labels, the best way to find out the product dimensions is to consult the manufacturer. Or, if you are making the products yourself, check the blueprint of the product, as it will have the dimensions used during production. These are the most accurate and reliable. For home-based businesses manufacturing fragile products like candles, it is best to measure the product after production.

Before we proceed ahead and explain how you can measure a box for fragile items’ shipping, please keep in mind that the dimensions you calculated here must not be used for shipping cartons. It requires some cushioning and accessibility allowance as well. Let’s learn how you can find out the perfect size for shipping boxes.

Now that you have the product dimensions, getting the right box size for fragile products is not that difficult. All you have to do is add 1-2 inches of cushioning space on each side of the box. For example, if your product measures 5 x 6 x 3, the ideal box size will be 7 x 8 x 5. This way of measuring a box for fragile items will allow you to place the product easily and also provide enough space for protective add-ons like cardboard inserts, bubble wrap, foam sheets, and packing peanuts.

Now here comes the most technical part of our custom box measurement guide. If your product has some extra accessories, you need to take that into account as well while finding the box size. The best packaging for fragile items ensures that all elements inside the box stay safe and protected during shipping.

Let’s consider one example here. For example, if you are selling electronics accessories like headphones or game controllers, and you want to add batteries or some other components to them. For such products, selecting the right box size is not that difficult but technical, especially for startups or small businesses. You have to include the allowance for extra accessories as well and include notches or pull-tabs so that buyers can take out the product easily. All of this can get a bit confusing and can lead to mistakes if not properly executed. In such a situation, you can end up wasting your valuable resources. We suggest you call our customer service representatives and seek answers to all your questions, as our free design support is specifically designed for all brands.

Packaging solutions for delicate products aren’t always about the shipping box dimensions. They are much broader and wider than that. While a perfect size prevents free movement and helps keep the cost in check, the right materials and inserts amplify the protection factor.

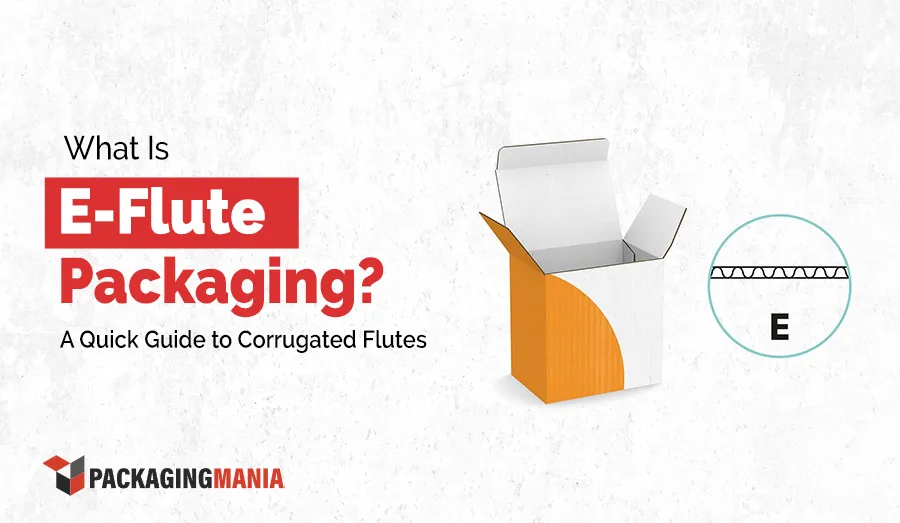

There are various packaging materials that can be used for manufacturing Custom Boxes. However, when it comes to fragile items, only corrugated stock is recommended. There is no denying the fact that it is a costly option compared to cardboard and Kraft, but spending more is a much better option than facing returns or customer complaints about broken or damaged products.

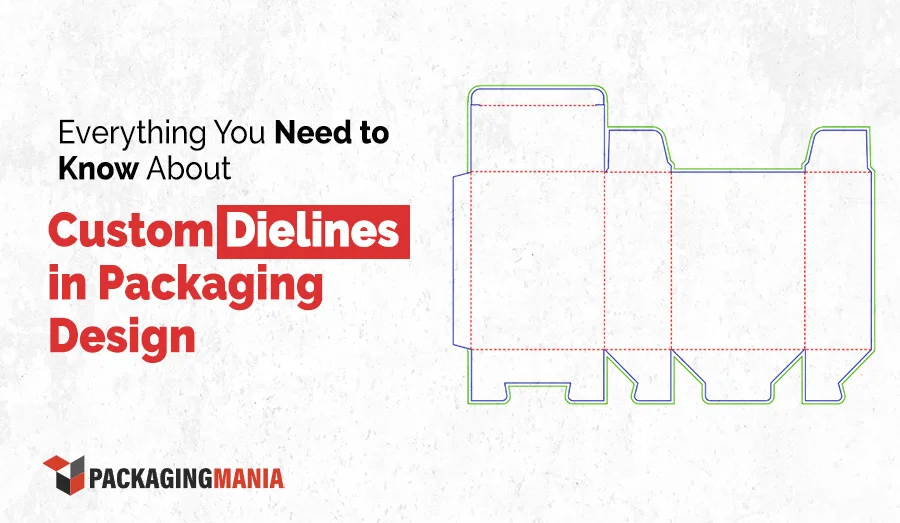

There are different profiles of this paper, which are referred to as flutes. These flute types affect thicknesses, cushioning, stacking strength, and printability. Here is an overview of different flute types to help you select the best material for your brand’s shipping boxes.

In order to pick the right shipping packaging for fragile products, you must know about the different wall types in corrugated stock.

There are various tests that help determine the box strength. The common tests are mentioned below to help you.

Fragile items require maximum care and protection during shipping. There are various things that can be used as custom box padding to enhance the protection factor.

Our packaging experts have identified some industries that require highly durable packaging for a few of their fragile products. Let’s check out some practical packaging tips for fragile items.

In apparel, the most delicate and fragile products include eyeglasses and sunglasses. For Custom Eyeglass Packaging, use rigid or corrugated inserts that ensure the glasses stay scratch-free during shipping. You can also use microfiber pouches for maximum protection and safety for glasses. To provide a better unboxing experience to buyers, pack the glasses in a rigid box with magnetic closure and then place it in a glasses shipping box made from corrugated container. You can use packing peanuts to fill the void between the boxes.

There are plenty of fragile and delicate products that need extra durable shipping packaging. For example, Mobile Battery Packaging must be made from double-wall E-flute corrugated stock for maximum shock absorption and a sleek appearance. If a buyer has ordered multiple items like chargers, earbuds, or cables, use foam inserts or pulp trays to create a protective shipping box. You can also use tamper-proof seals to guarantee buyers that the box has not been opened during shipping.

In this industry, wines, glasses, and crockery items demand maximum protection. For example, if you are looking for a Wine Bottle Shipping Box, you must use double-wall or triple-wall corrugated board to increase drop resistance. Although high-end wines come in rigid boxes, you still need to work on shipping boxes to make them sturdier. A box for shipping wine must be as elegant as the drink inside; this is why it is important to get them printed with a custom print.

There are countless products in the retail industry that deserve solid protection and support during shipping. However, we have heard many complaints about candle shipping boxes from our clients, and we have solved all of them with our highly exceptional custom packaging solutions. We always suggest our clients use double-wall or triple-wall corrugated cardboard for candles, as they are brittle and require utmost support from all sides. You can use packing peanuts or foam inserts around the sides if you want to provide a premium unboxing experience to buyers.

Brands selling candles in glass containers must pay special attention to their fragile candle packaging. The glass container must not move in any way; otherwise, it can break during shipping. If you want to explore how our packaging solutions make a difference to your business, Check Out Our Custom Candle Boxes.

We have covered almost everything related to shipping fragile items in our dimension guide for custom boxes. If there is anything else you would want to know, we are here to help you out. For example, if you want to create protective packaging for glass items but you don’t know about its details, simply call us and we will take care of all your requirements.

Most brands are now using custom printed boxes with tailored sizes, shapes, and padding to remove any dangers related to shipping. Are you still using generic boxes and filling them up with excessive fillers? You are not doing the right thing. Switch to custom shipping boxes right now and take your brand and its products to new heights of success.

16 July 2025

28 June 2025