By Blake Harper 19 June 2025

Today, more people are worried about climate change and the growing problem of waste harming our planet. Because of this, the packaging world is changing in a big way. One major change is the move toward using safe materials for the Earth. Many companies are now choosing biodegradable options that break down naturally over time. These smart choices help lower pollution and cut down on harmful plastic waste. Instead of sitting in landfills for hundreds of years, these materials return to nature safely. Hopefully, this shift will lead to a cleaner, greener future. From food packaging to shipping supplies, even eco-friendly boxes are becoming more popular. They are made from earth-safe materials that don’t hurt the ecosystem. In this comprehensive guideline, you will walk through some amazing biodegradable packaging materials and how they help protect the planet. Continue to read ahead for more information!

Here is a detailed breakdown of biodegradable packaging material options you need to know;

Corrugated cardboard is made from paper, which comes from trees. It is completely natural and safe for the planet. When you throw away this packaging material, it breaks down with the passage of time. Rain, sun, and tiny bugs help it turn into soil. That means it doesn't stay on the ground forever like plastic. Not only this, but people can also recycle this material and use it again and again. This makes it an eco-friendly choice for packaging that keeps things while being kind to nature. As a business owner, investing in what is good for the planet is a smart move.

If you're looking for sustainable packaging, recycled paper is a great choice. It is made from old paper used by people, schools, and businesses. Instead of throwing this paper into the trash, it gets turned into new packaging. This helps stop pollution as well as saves water and energy. According to the Environmental Protection Agency (EPA), recycling one ton of paper can power a home for 6 months, save 7,000 gallons of water, and stop 60 pounds of air pollution. Choosing this kind of biodegradable packaging material helps the Earth and keeps waste out of landfills.

Another biodegradable option for custom packaging boxes is reusable materials. They can even be reused for future shipments, such as bins, bags, boxes, or anything else that can be used again. It eliminates the need to use many new materials for creating the packaging. Reusable materials are not only strong but also last longer. This helps prevent your fragile things from breaking down during transit. These perks make reusable packaging materials an economical option for businesses and consumers alike. With so many options available, it can be hard to decide which material to pick, right? Well, going for reusable materials is a suitable option here.

Polylactic acid (PLA) is a special kind of plastic made from plants like corn or sugarcane. PLA is better for the planet as it doesn't come from oil. This acid is used in many things, like clear food boxes and medical tools that break down safely. Since PLA comes from natural sources, it is called bioplastic as well. It can be composted in big compost centers, helping turn it back into soil. This means less trash and less harm to the ecosystem. PLA also helps you reuse and recycle more, which is a part of the smart system called the circular economy. If you want to create packaging that sells faster and is safe for everyone, polylactic acid is the ideal material option.

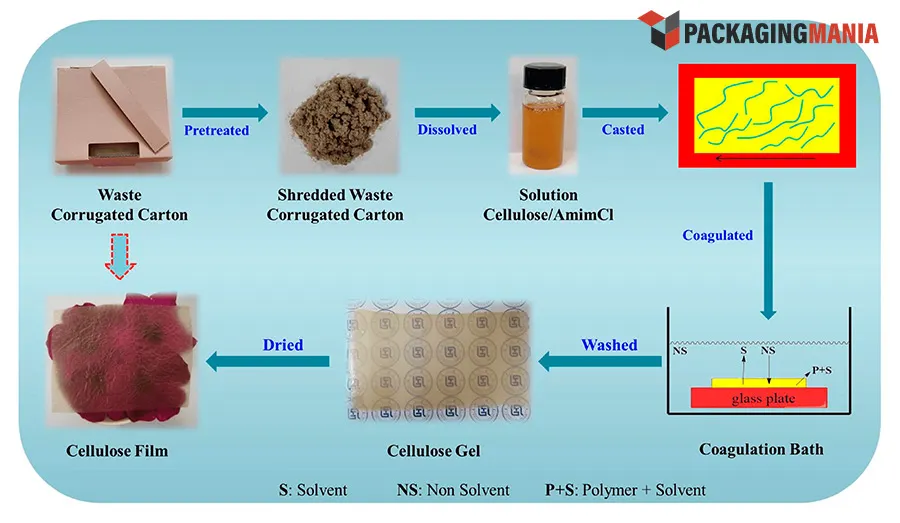

Cellulose-based films come from cellulose found in the cell walls of plants. These films look clear like plastic and let air pass through. It is a great choice for keeping fruits, vegetables, and other edibles fresh for a longer period. Today, people are making more use of this kind of packaging to wrap food and other items. They are fully biodegradable because they can be composted without making any waste. Cellulose-based materials have no carbon footprint compared to synthetic alternatives. With advanced technologies, these old plant-based ideas are now helping the world in a modern way. You must ensure to use plant-based boxes to attract eco-conscious buyers.

Starch-based bioplastics are made from plants, like potatoes and tapioca. These are safe for the Earth as they come from things that grow back. Microbes and tiny bugs help them turn into soil just like leaves of food scraps do. The speed of biodegradation depends on the starch content, additives, and environmental conditions, such as moisture and temperature. This is what makes these bioplastics a much better choice than regular plastics. Starch bioplastics can be soft or hard, so they work well for many kinds of packaging. They are used to make foam that protects products in boxes. Companies also utilize this material to craft bags that degrade with time.

Mushroom mycelium packaging is an innovative way to help the Earth. It uses the roots of mushrooms, called mycelium, to make safe food packaging. The mycelium grows around farm waste like corn husks or straw. It forms into strong shapes that can efficiently hold food and several other goods. This kind of packaging is soft and can protect things, including breakable plates or glasses. Mushroom mycelium packaging works like foam but is completely made from nature. You can craft this type of packaging in many sizes for a snug fit. If you're a retail brand searching for ways to draw the attention of more people to your products, go for this packaging.

Mushroom Sheets or Panels (mycelium composites )- 10mm to 50 mm (1 cm to 5 cm)

Custom-Molded Mushroom Packaging (for cushioning) - 20 mm to 100 mm (2 cm to 10 cm)

Thin Mushroom-Based Liners (less common) - 5 mm to 10 mm

Chitosan is an organic material made from chitin, which comes from the shells of shrimp and other sea creatures. Tiny microbes help chitosan decay into natural parts like water and soil. Not only this, but this material also fights fungi and bacteria, which helps retain the taste of food. It is safe, non-toxic, and compostable. That is why companies are using chitosan to make packaging and foam. It reduces the waste caused by plastic and pollution while keeping the planet clean. Want an excellent packaging solution for your delicate items? The shock-absorbing properties of chitosan offer next-level protection to your products during storage and shipping.

Pulp thermoforming turns old paper and cardboard into strong, earth-friendly packaging. The process involves applying high temperatures and pressure to wet paper pulp to shape trays and boxes. These products are sturdy but also break down easily after use, making them good for the planet. Instead of throwing away paper waste, this method gives it a new life in a useful form. It helps cut down on trash and supports recycling efforts. Pulp packaging is a smart way to keep things safe while caring for nature. It is a great choice for companies that aim to promote a sustainable future. This method turns everyday paper waste into something helpful and green.

Seaweed is natural, renewable, and breaks down quickly without harming the planet. Unlike plastic, which takes hundreds of years to decompose, seaweed can dissolve in water and soil in just a few weeks. It grows fast and doesn't need fresh water, fertilizer, or pesticides. This makes seaweed a very eco-friendly resource for packaging. Seaweed is also safe for both plants and animals, even in edible forms. Using seaweed helps reduce plastic waste and ocean pollution. Many brands are now using seaweed packaging to replace harmful plastics. So, if you're about to create custom boxes for your retail products, be sure to use seaweed as a packaging material.

Bagasse is what is left after sugarcane is crushed to get juice. Instead of throwing it away, people use it to make things like food containers. Among other biodegradable packaging materials, bagasse is also an ideal choice. It can be shaped into bowls, plates, and boxes. Plastic and foam can hurt nature, which is why you should always go for earth-friendly options. Using bagasse also means you're not wasting parts of the sugarcane plant. Generally speaking, it is a great way to turn leftovers into something really useful. No matter what types of products you want to hold and store, bagasse has always been one of the best material options for sustainable packaging.

Above all, the next biodegradable material you should opt for is palm leaves. These leaves are cleaned and pressed into strong containers without using harmful chemicals. They decay naturally within a few months while turning into nutrient-rich compost that helps plants grow. Palm leaves are resistant to oil and moisture, making them perfect for food packaging. Since palm leaf packaging is made with low energy and water use, it has a smaller carbon footprint. Well, the benefits don't just end here. This type of packaging is highly durable and can be reused several times before composting. All these factors make palm leaf packaging an excellent choice.

Wool is a natural, renewable fiber. It has found its way to the packaging industry as an insulation material. The natural structure has a great tendency to trap air, so it won't damage the items inside. This reduces the need for extra packs and plastic for packaging. Wool insulation packaging is lightweight, flexible, and can be compressed for easy transport. It doesn't pollute the planet and doesn't stay in a landfill for years. Whether you run a retail shop or a small business, the right packaging can take your business to new heights. When creating packaging boxes, be sure to go for materials that are strong and also safe for the environment.

Hemp and Bamboo are also famous biodegradable packaging material options. Using these plants as a packaging material helps keep the planet free from toxins and makes it healthy for everyone. Hemp is a tough fiber used for clothes and paper. It is now also widely used in the packaging industry. Bamboo grows very fast and fights against germs that could damage your products. It is naturally antimicrobial, which means it won't harbor bacteria the way some other materials can. This is what makes bamboo a much safer choice to be used for the packing of edibles. Both plants can be reused multiple times before the process of recycling or composting.

Kraft paper is specially designed for use in packaging applications. It has excellent properties, like durability and good strength. If you want to give your two piece boxes a natural and organic look, kraft paper is ideal to go for. The strength of this material makes it great to hold heavy-duty items, while the biodegradability helps reduce pollution. Despite its sturdiness, Kraft paper is lightweight, which can reduce shipping costs. This balance makes it a top choice for eco-friendly packaging. The production process of Kraft packaging paper eliminates contamination risks as well. Food brands must take advantage of using this packaging material.

Glassine is a shiny, smooth paper that is good for transparent packaging. It is both recyclable and biodegradable at the same time. Glassine is pure paper with no plastic or waxy layers. It doesn't even have any acid, meaning it won't hurt the things it touches. Adding more to this, glassine is also pH-neutral, which helps keep your products completely safe. You can make use of glassine packaging to pack paper goods, snacks, or a lot of other small items. While its production uses some energy, it offers a sustainable alternative to plastic bags and wraps. If you need see-through packaging that is safe for people and the Earth alike, glassine is worthwhile.

Green cell foam is a biodegradable material made from natural, non-GMO cornstarch. It degrades into soil within just 4 weeks and is fully compostable. Green cell foam can also dissolve in water, making it easy to throw away while keeping the planet safe. It tends to protect fragile items by absorbing shocks during transportation. For businesses, green cell foam packaging helps show you care about the environment. This makes your brand look good to customers who want eco-friendly options. Almost everyone is opting for sustainable packaging these days. To stand out in the crowd, you need to create boxes that look great and also keep the planet clean.

The future of biodegradable packaging materials looks super bright and exciting. As the world is fighting plastic pollution, new eco-friendly materials are being created every day. Scientists and companies are now using things like mushrooms, seaweed, cornstarch, and even banana peels to make packaging. These materials are not only safe but also break down quickly without leaving any waste behind. Adding more to all this, some packages can be even eaten or melted in water. In the near future, you will see smart packaging that tells if food is still fresh or wraps that keep your edibles safe without plastic. Many countries are now making rules to ban harmful packaging, which means sustainable boxes will be seen more in retail stores. With these innovative changes, biodegradable packaging is the ultimate way to a cleaner and greener world.

With rising pollution these days, it is difficult to stand out in the crowd. Eco-friendly boxes are no exception here. There are so many biodegradable materials out there. Choose the material wisely when creating packaging, as it shows your dedication to dealing with environmental challenges. They are crucial for reducing waste, conserving resources, and keeping Earth safe. No matter what type of custom boxes you need to create, Packaging Mania is the one-stop solution for all your needs. Whatever custom packaging boxes we craft, they are all 100% recyclable, biodegradable, and also completely safe for the environment.

16 July 2025

28 June 2025